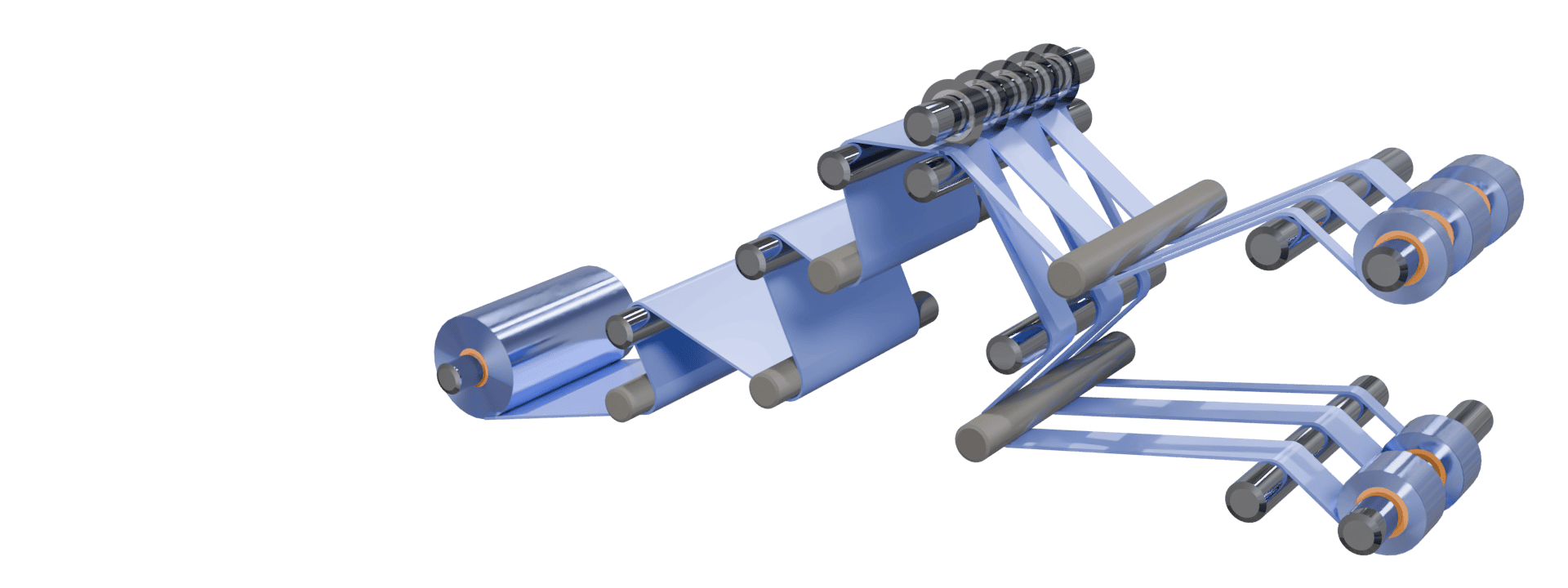

1. Slitting

Slit width: from 5 mm

Maximum material width: 750 mm

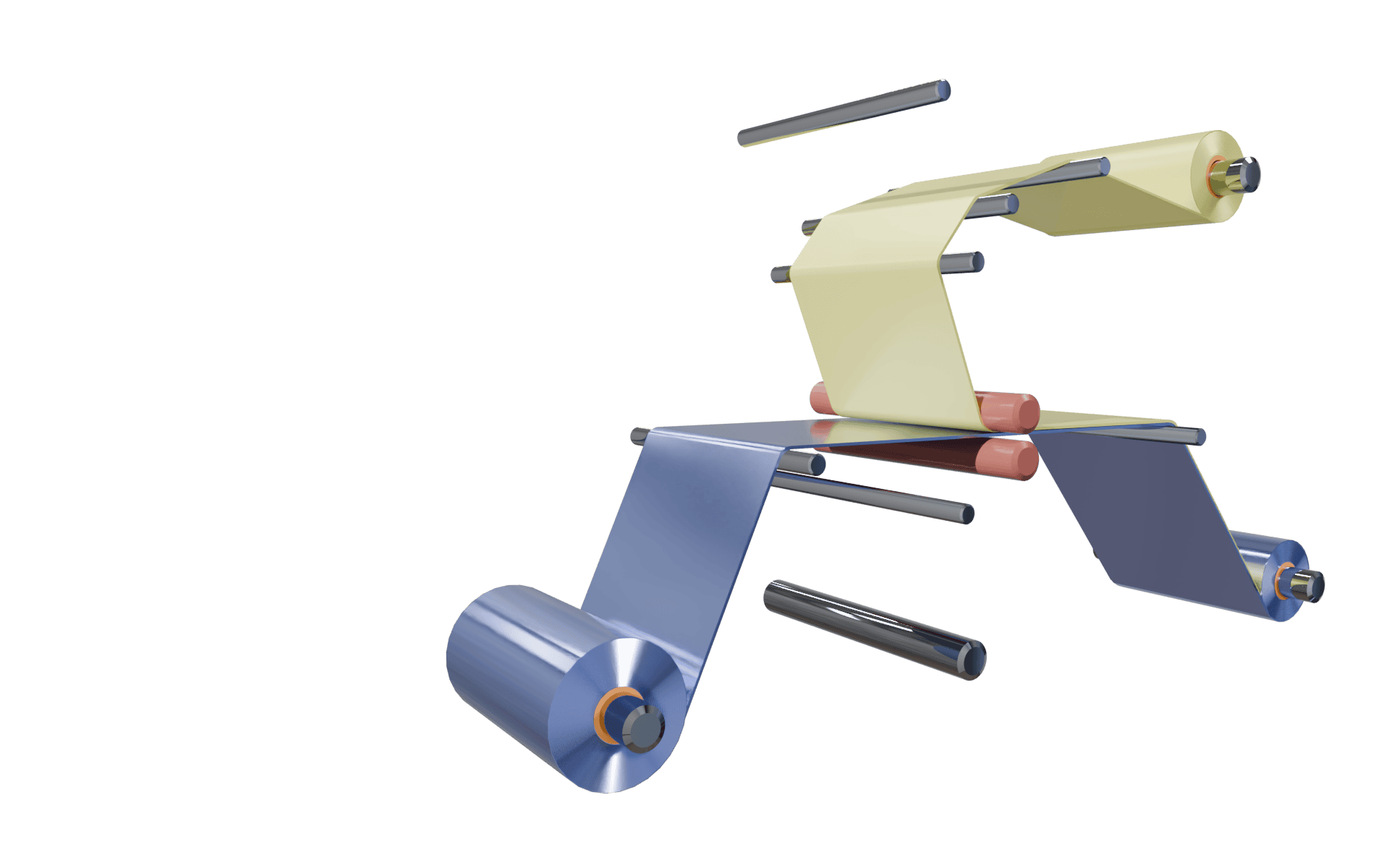

2. Laminating

Product shafts: 3 shafts; maximum width 700 mm

Simultaneous whole area pasting

Patial laminati

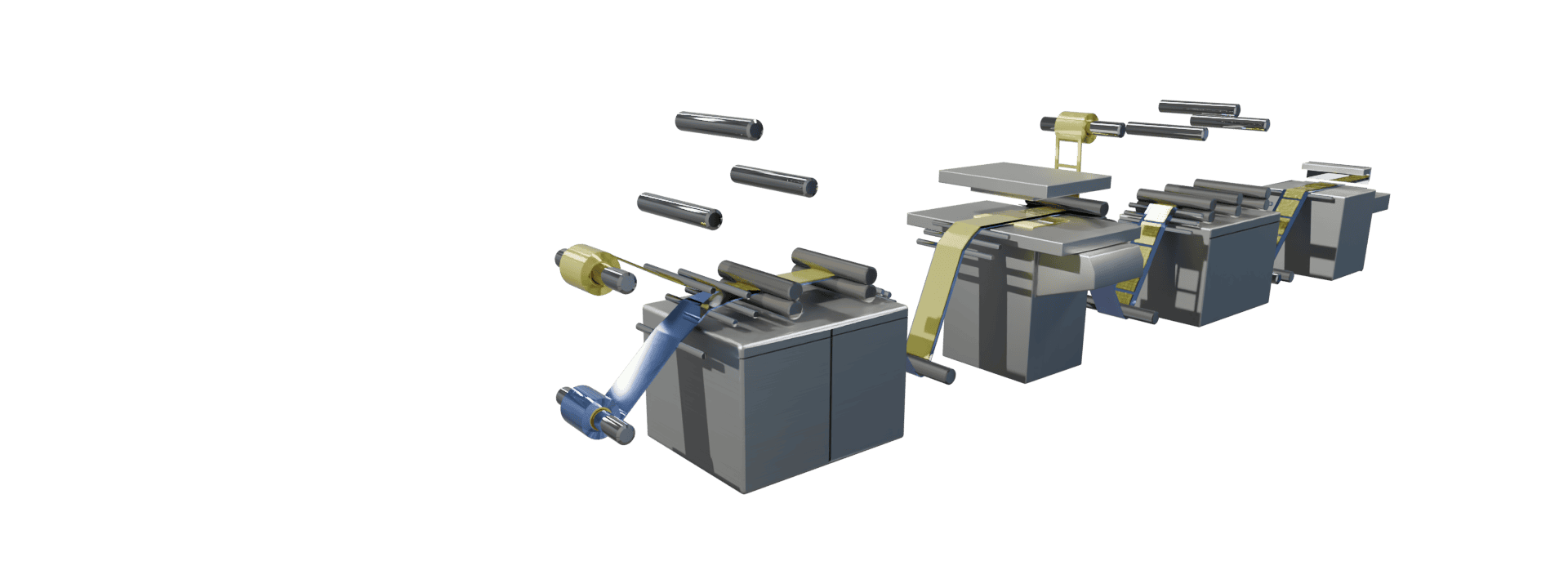

3. Die Cutting (Blanking)

Integrated process possible: lamination → pressing → flash removal → sheet cutting

Punching for multiply combined materials

(copper foil; abrasive materials; nonwoven fabric; stainless foil; plastic film)

Supported die types: Vick die, etched blade, engraved blade, metal mold

4. Inspection and Packaging

Visual inspection, Magnifying lens, Stereomicroscope

Toolmaker's microscope

5. In-house Automation Equipment

- Line examples: unwind → alignment → adhesive placement onto dispensers → thermoforming of dispensers

- After press blanking: liner replacement, scrap removal → sheet cutting

- Automatic feed systems to packing machines

- Various sensors installed for detecting blanking or feed abnormalities

6. Prototyping and Tool Design

Prototype production and from drawing process flow

Determination of a suitable punching die

Rapid prototyping of irregular-shaped parts using CAD plotter

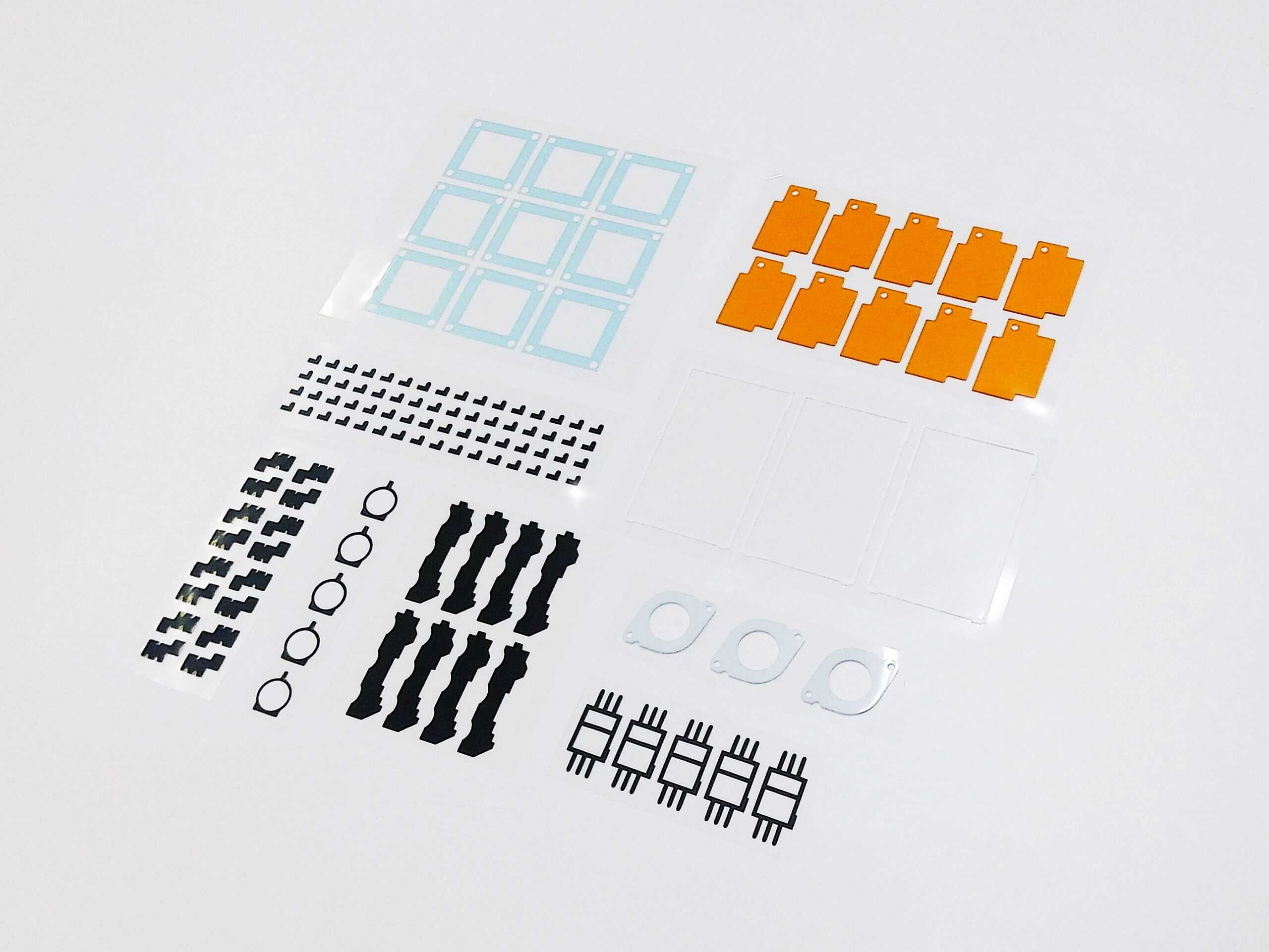

Processing Samples

Typical sample tooling: Vick die, Pinnacle die

Also possible with engraved blades and metal molds.